Lobster-i

Full control of your AD reactor's feeding rate

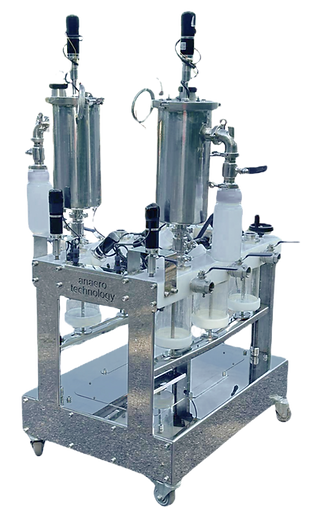

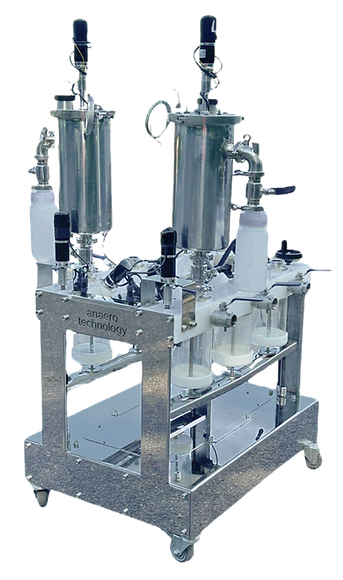

2 reactors for photography purposes

What's included:

-

4x 5L Lobster Set

-

4x Automatic Feeder

-

PLC Control Panel

-

6-Cell Gas Flow Meter

-

Arduino Data Logger

-

1-Year Warranty

Optional modifications:

-

Larger reactor sizes (enquire)

-

Pressure valve for higher pressures inside reactor

-

PH probe

All for £26000

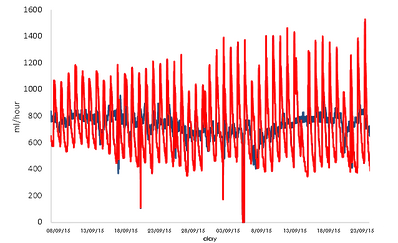

A key variable in full-scale anaerobic digestion is the feeding rate, which is adjusted to optimise reactor health and biomethane production. Automatic feeding avoids spikes in gas production, producing a more consistent gas production profile which closely represents the full scale operation, even at the microbial scale (ie. you don't cycle between overfeeding and starvation).

The Lobster-i is specifically designed to take full control over your reactor's feeding rates, with each of the 4 reactors having its own automatic feeder. This means you can run 4 completely different experiments from the same machine, enabling vast research capabilities.

Unlike the common batch test, our automatically fed machines can be run continuously, intaking more feedstock, and removing excess digestate. This allows you to evaluate the effect on gas production from a range of variables - including the feeding rate.

Blue line showing automatic feeding gas production, much more consistent than semi-continuous (red line).

Use real feed in your digester to replicate the industrial process as closely as possible. In our lab, we have been using roughly 19% DS mixtures of food-waste. As the feed is delivered into the reactor, agitators homogenise the mix so the feed is kept consistent throughout.

4 Reactors

4 Auto-Feeders

Experiment with 4 different feeding rates at once. The perfect tool for those who wish to model the running of more than 1 automatic AD system, or who wish to compare the effects of changes such as feeding rate or additive use

The robust stainless steel reactors provide the non-reactive environment for anaerobic digestion. Enquire for different reactor volumes.

The easily removable effluent bottle collects the excess digestate to avoid pressure build ups and spillages.

4x 5L Reactors

1L Effluent Bottle

4x Automatic Feeder Syringe

The patented feeder syringe feeds the reactor at your programmed rate. It prevents backflow from the reactor and a full syringe feeds for about a week.

2 reactors for photography purposes

Mixer motor

Each reactor comes with a 20 rpm motor which constantly mixes the inside of the reactors.

Heater Jacket

The custom fit heater jackets maintain a consistent, programmable temperature inside the reactor.

Agitator Motor

To ensure homogenous feed, the agitator mixes the feedstock coming up from the feeding syringe.

Our open source Arduino data logger records and stores the gas production data measured by the gas flow meter. When an event happens in the gas flow meter, a reed switch circuit is closed which is logged by the data logger. The BMP280 pressure sensor and thermocouple inform the data logger to automatically convert any gas volumes to STP. Data is easily extracted at any time through USB connection with any computer.

%20(1).png)