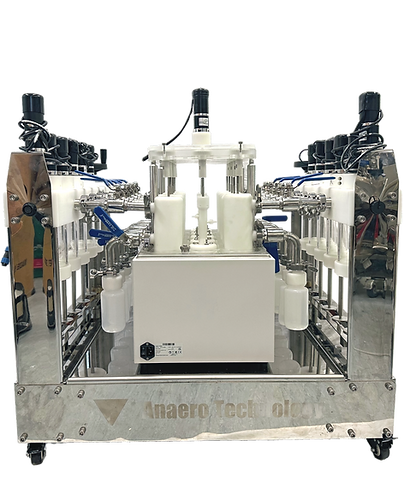

Available as a stand alone machine or an upgrade on the BMP Nautilus, the Medusa combines batch feeding and automatic feeding, with 10 auto-fed and 5 batch-fed reactors. If you already have a BMP but want to model the OLR of real anaerobic digestion plants, then the Medusa is a perfect compromise between quality data and affordable lab equipment.

The small reactor volume (1L) and automatic feeding capabilities make the Medusa compatible with low total solid substrates such as: municipal or industrial wastewater, leachate, and other soluble organic effluents.

The feeding syringe holds roughly a week's worth of feed, meaning quality data that represents industrial scale OLR's doesn't come with time-intensive manual feeding. Generate all your necessary data on your feedstock with 1 machine and minimal effort.

Experiment with different feedstocks and feeding rates all at the same time with 15 total reactors. You also get the freedom to use repeat reactors and controls with just inoculum, for the most robust research data.

10 Auto-fed Reactors

Simply input your feeding rate into the control panel, top the feeding syringe up (lasts about a week running continuously) and collect data resembling the feeding regime of a full-scale plant.

5 Batch-fed Reactors

With 5 batch-fed reactors you can determine the biomethane potential of your feedstock, or simply test your inoculum to measure its activity (RBP). Use this to judge your feedstock's value - just like the BMP Nautilus machine.

10x Auto-fed Reactors

HDPE reactors are non-reactive and individually tested for gas tightness

500ml Effluent Bottle

The easily removable effluent bottle collects the excess digestate to avoid pressure build ups and spillages.

Mixer motor

All 15 reactors are mixed are the exact same rate of 20rpm

Waterbath

The Grant water bath maintains a consistent temperature for the reactors - up to 85°C.

Agitator Motor

To ensure homogenous feed, the agitator mixes the feedstock coming up from the feeding syringe.

Automatic Feeder Syringe

The patented feeder syringe feeds at your programmed rate. A full syringe feeds for about a week.

5x Batch-fed Reactors

HDPE reactors

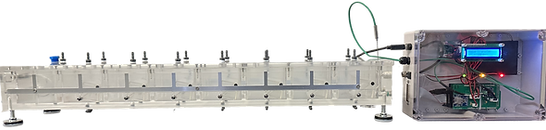

Custom 15-cell gas flow meter measures gas production in ~15ml increments (subject to calibration)

Our open source Arduino data logger records and stores the gas production data measured by the gas flow meter. When an event happens in the gas flow meter, a reed switch circuit is closed which is logged by the data logger. The BMP280 pressure sensor and thermocouple inform the data logger to automatically convert any gas volumes to STP. Data is easily extracted at any time through USB connection with any computer.

%20(1).png)