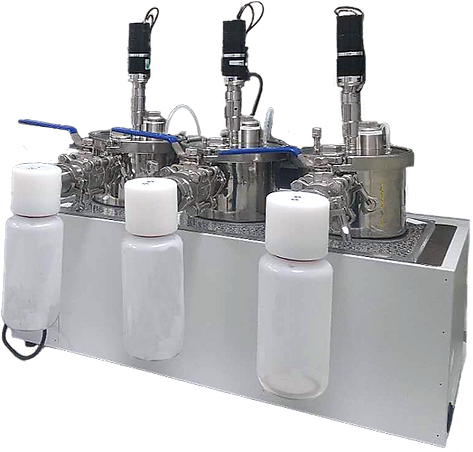

Top up your digester's feed as often as you like with the manually fed Pegasus. Frequent feeding reduces the shock loading effect from large sudden feeds, and produces more consistent gas production profiles, resembling those of industrial digesters. Run the Pegasus parallel to a full-scale AD plant with the removeable effluent bottles to give the digester space to run continuously.

The Pegasus is a great option when automatic feeding isn't necessary, but you still need a digester to run continuously. It is also specifically engineered to deal with challenging feedstocks with high solids, or fibrous content such as: agricultural residues, sileage or animal waste.

Manually feed as frequently as you like without compromising the anaerobic setup. You can reduce the shock to the digester that comes from large irregular feeds. Simply remove the gas-tight cap, insert your feed and put the cap back on.

Large reactor volumes

The large reactor volume facilitates plentiful gas production, allowing for regular gas analysis and longer retention studies.

Manual Feeding

Simple and reliable, manual feeding gives you control over your digester's feedstock intake, allowing you to customise the process to your requirements.

Use any type of feedstock including total solids content up to 100%, by using the manual feeding port.

Feeding Port

Large cap is removed when feeding.

1L Effluent Bottle

The easily removable effluent bottle collects the excess digestate to avoid pressure build ups and spillages.

Mixer motor

Each reactor comes with a 20 rpm motor which constantly mixes the inside of the reactors.

5L Reactor

Large stainless steel reactor provides environment for anaerobic digestion.

Water Bath

Grant water bath reliably controls temperature, from ambient temperature up to 85°C.

Our open source Arduino data logger records and stores the gas production data measured by the gas flow meter. When an event happens in the gas flow meter, a reed switch circuit is closed which is logged by the data logger. The BMP280 pressure sensor and thermocouple inform the data logger to automatically convert any gas volumes to STP. Data is easily extracted at any time through USB connection with any computer.

%20(1).png)